Our New Location

Area provides real insights, without the data overload.

100,000 Sq. Ft. Facility

From our 100,000-square-foot facility in Wills Point, Texas, we handle every step of the fabrication process under one roof

When you’re building equipment that carries your name, the components you source matter. MSM Mechanical understands the pressure OEM manufacturers face to deliver reliable products on predictable schedules. That’s why we’ve built our business around complete in-house control.

From our 48,000-square-foot facility in Terrell, Texas, we handle every step of the fabrication process under one roof

Area provides real insights, without the data overload.

100,000 Sq. Ft. Facility

From our 100,000-square-foot facility in Wills Point, Texas, we handle every step of the fabrication process under one roof

Design and

Engineering

Design and

Engineering

Design and

Engineering

Design and

Engineering

Amplify insights, and visualize your growth

Amplify Insights

When you work with MSM, there’s no handoff to third-party shops, no delays waiting on subcontractors, and no quality inconsistencies between vendors, just straight accountability through the whole process.

Visualize Growth

Our focus is on serving manufacturers who integrate our work into their products, including companies that build air compressors, process equipment, agricultural machinery, and industrial systems.

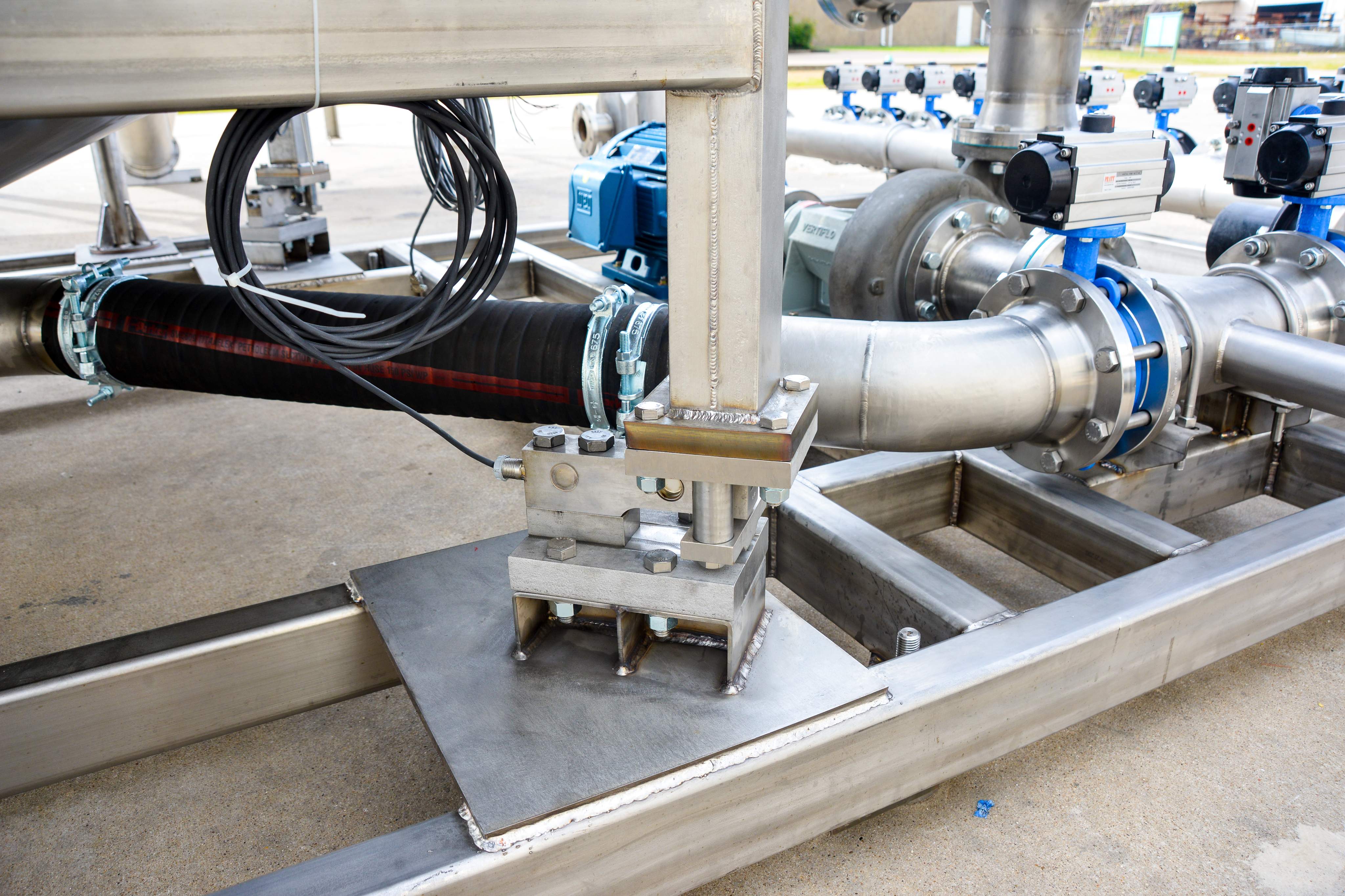

Our core fabrication division handles custom mechanical systems from concept through completion. Whether you need structural frames, precision assemblies, or production runs of identical parts, we have the equipment and expertise to build it right. CNC plasma cutting up to 10' × 40', heavy press brakes up to 325 tons, and full machining capabilities mean we can tackle complex projects without farming out critical operations.

As an ASME U-stamp certified shop, MSM Tanks fabricates code-compliant pressure vessels in both mild steel and stainless steel. We know the equipment manufacturers who rely on us can’t afford delays or failures in the field. That’s why every vessel we build meets ASME Section VIII standards and undergoes rigorous testing before it ships. From single custom tanks to production runs for OEM partners, we maintain the same exacting standards.

J. May Equipment Group brings decades of specialized expertise in liquid mixing systems and complete plant design. Now integrated with MSM's fabrication capabilities, J. May engineers custom solutions for agricultural, oilfield, animal feed, and industrial applications. Whether you need a single high-performance agitator or a turnkey mixing facility, J. May delivers systems built for reliability and long service life.

What sets MSM apart is our combination of technical capability, production flexibility, and single-source accountability. When sourcing components that become part of your finished product, you need a partner who understands the risks involved.

Whether you are looking to develop a new product, scale up production, or are looking for a more reliable fabrication partner, we’e ready to help. Our team can review your specifications, offer practical insights on manufacturability, and provide transparent timelines and pricing.